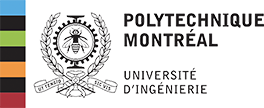

Pensky-Marten Flash Tester (Fisher-Tag)

This apparatus measures flash points of fuel and lube oils, suspensions of solids, liquids that tend to form a surface film under test conditions, and other liquids. ASTM D93 must be followed in order to use this equipment.

Main specifications

| Temperature range: | 40-370°C |

| Sample volume: | >75 mL |

| ASTM: | D93 |

| Location: | A-676 |

TGA Q50 (TA Instruments)

Thermogravimetric analyzer (TGA) is an instrument relying in a high degree of precision in mass change, temperature and temperature change. These measurements allow different applications of the equipment: decomposition characterization of materials, study of reaction kinetics and degradation mechanism, determination of organic and inorganic content in a sample.

Main specifications

| platinum pan: | up to 1000°C |

| ceramic pan: | up to 600°C |

| Thermocouple: | Platinel II |

| Heating rate: | 0.1 to 100⁰C/min |

| Precision (isothermal) ± 0.1°C | |

| Helium, nitrogen, oxygen, air, argon | 1000 to 50°C < 12 min |

| Purge gases: | Helium, nitrogen, oxygen, air, argon |

| Hydrogen or other explosive gases are not authorized in the TGA | |

| Corrosive gases are not authorized in the TGA | |

| Oxygen can bused as a purge gas in the TGA. However, the furnace must be kept clean so that volatile hydrocarbons, which might combust, are removed | |

| Purge gas flow rate: | up to 200 mL/min; in our equipment we use 40 mL/min |

| Maximum sample weight: | 1g (depending on the pan) |

| The amount and rate of weight change in a material pan (aluminum, platinum or alumina ceramic pans) | |

| The total mechanical capacity of the balance is 5 g. Thus, never allow the total weight of the sample, tare weight, hang-down wires, and pans to exceed 5 g. | |

| Resolution: | 0.1 µg ; Accuracy ≤ ± 0.1% |

| For 200 mg range: | 1 µg |

| For 1 g range: | 0.1 µg |

| Location: | A-560 |

TGA Q5000 (TA Instruments)

Thermogravimetric analyzer (TGA) is an instrument relying in a high degree of precision in mass change, temperature and temperature change. These measurements allow different applications of the equipment: decomposition characterization of materials, study of reaction kinetics and degradation mechanism, determination of organic and inorganic content in a sample.

Main specifications

| Ambient to 1200⁰C | |

| platinum pan: | up to 1000°C |

| Ceramic pan: | up to 600°C |

| Heating rate: | 0.1 to 500⁰C/min |

| Accuracy (Isothermal) ± 1°C | |

| Furnace cooling (forced air/N2): | 1200 to 35°C < 10 min |

| Purge gases: | Helium, nitrogen, oxygen, air, argon |

| Hydrogen or other explosive gases are not authorized in the TGA | |

| Corrosive gases are not authorized in the TGA | |

| Oxygen can be used as a purge gas in the TGA. However, the furnace must be kept clean so that volatile hydrocarbons, which might combust, are removed | |

| Purge gas flow rate: | up to 200 mL/min; in our equipment we use 40 mL/min |

| Maximum sample weight: | 100mg |

| Resolution: | Weighing Accuracy ± 0.1% / Weighing Precision ± 0.01% |

| Location: | A-560 |