Hydrodynamics Modelling and Catalytic Reactions of Multiphase Reactors at Extreme Conditions

RESEARCH PARTNERS

RESEARCH GROUP MEMBERS

Supervisor & Senior Researchers:

JAMAL CHAOUKI

SHULI SHU

Graduate Students:

EL MAHDI LAKHDISSI

IMAN SOLEIMANI

MOJTABA MOKHTARI

Owing to the shortage of traditional resources and stringent environmental constraints, the feedstocks of several industrial processes are rapidly changing. The intrinsic variability of the feedstocks combined with social needs make many industrial processes much more difficult to design and operate. Scrutinizing the hydrodynamics and catalytic reactions of multiphase processes under conditions applicable to a broad range of technologies would lead at providing valuable insights into how the variation of operating condition can modify the reactor’s hydrodynamics and, in turn, its performance. The knowledge achieved from these studies, consequently, will help in the development of new processes and/or in the improvement of the existing ones to be aligned with the current and future needs.

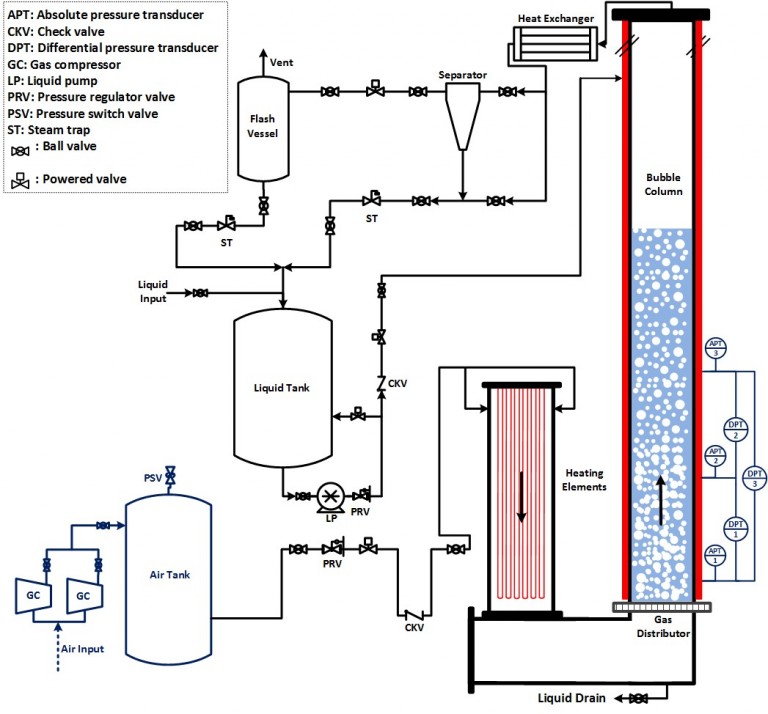

In this regard, a research project includes three integrated research themes (turbulent fluidized beds reactor, slurry bubble column reactor, and catalytic reactions of multiphase reactors) have been tailored to the industrial needs. The industrial partner of this research project is TOTAL American Services, Inc. Two pilot-scale reactors have been built to carry out the experimental work (1) a gas-solid fluidized bed (I.D.=15 cm, H=4 m, P=0.1 to 3 MPa, T=20 °C to 1190 °C), and (2) a slurry bubble column (I.D.=15 cm, H=4 m, P=0.1 to 3 M Pa, T=20°C to 250°C).

Hydrodynamics of a Gas-Solid Fluidized Bed at Elevated Pressures and Temperatures

William Roy

Gas-solid fluidized beds are widely adapted in chemical processes operated at moderate to high pressure and temperature. The hydrodynamics of fluidized beds at elevated pressures and temperatures directly affects the transfer phenomena and reaction rates in the bed and, hence, is a critical factor for their design and operation. Nevertheless, the present understanding is far from satisfactory due to the lack of insight about the relative importance of interparticle forces and hydrodynamic forces. Attention to the fluidization characteristics of high pressure and temperature gas-solid fluidized bed reactors is essential since they will find many additional applications in the near future that will coincide with the rarefaction of conventional resources. The objective of the present study is to explore the fluidization behavior of different particles, covering Geldart groups A, B, and D powders, referred to the fluidization behavior at ambient conditions, at different operating conditions. The operating pressure and temperature will vary in the range of 1–20 bar and 25–900oC, respectively. The fluidization study will be attempted at different superficial gas velocities covering the fixed bed state, bubbling, and turbulent fluidization regimes. Different reliable and accurate measurement techniques/approaches, i.e., pressure transducers, an optical fiber probe, and the gas residence time distribution measurement, will be employed for the purpose of a comprehensive hydrodynamic study from both global and local points of view.

Measurement of Simple Hydrodynamic Parameters in a Gas-Solid Fluidized-Bed at Elevated Pressures and Temperatures

Iman Soleimani

Gas-Solid fluidized beds are widely applied in chemical processing industry due to high contact surface, good mixing quality and high heat transfer capabilities.

It is found that operating the fluidized beds at elevated pressures improves the quality of fluidization. Also, high temperature is needed in fluidization units, such as combustors and cracking units. Change in the fluidizing gas properties, namely gas density and viscosity, is mostly responsible for the change in the bed behavior at extreme conditions, i.e., high pressure and temperature, which is defined by the effect of hydrodynamic forces (HDFs). At high temperature, interparticle forces (IPFs) also play an important role in determination of fluidization characteristics.

Available hydrodynamic based models and/or correlations are not adequately predicting the bed hydrodynamics at extreme conditions. So, the level of IPFs at different temperatures should be measured and a new correlations to predict simple hydrodynamic parameters, namely Umf and Uc, should be developed.

A pilot scale fluidized bed, 15 cm ID and 4.75 m height, capable of operating at pressures up to 30 atm and temperatures as high as 900 ˚C is being used in this study and the hydrodynamic parameters is being measured through analyzing the absolute and differential pressure signals in both time (mean value and standard deviation) and frequency domains (power spectral density analysis (PSD)).

This study will highlight the effect of extreme operating conditions, i.e., high temperature, on the fluidization transition velocities at different fluidization states, which is essential for a reliable design and scale up of such a gas-solid fluidized bed.

Hydrodynamics of Bubble Column Reactors Operating with Non-Newtonian Liquids at High-Pressure (HP) and High-Temperature (HT) Conditions

Mojtaba Mokhtari

Although different types of reactors are used as multiphase contactors, the bubble column reactors received much attention from both academic and industrial interests during the past decade. The bubble column reactors offer high rates of heat and mass transfer, less maintenance cost, and feasibility for large production capacity.

The design and scale-up of a bubble column reactor needs a complete understanding of its complex hydrodynamic behaviour, which is influenced by the physical properties of the phases, the operating variables and the design parameters. In recent years, viscous liquids (Newtonian and non-Newtonian) are being used for carrying out chemical reaction in bubble column reactors in many processes at HP and HT conditions.

Although there has been an increasing interest in using non-Newtonian liquids in bubble column reactors, knowledge of the effects of the non-Newtonian flow behaviour on the hydrodynamics of bubble columns is limited and extensive studies are still needed to elucidate the influence of these liquids on the performance of bubble columns.

To fulfill this essential need, the effects of different non-Newtonian liquids on the hydrodynamics of bubble columns is being investigated in two pilot-scale bubble column reactors with different geometries operating in both ambient and HP-HT conditions under the framework of the TOTAL research chair on multiphase reactors operating at extreme conditions.

Hydrodynamics and mass transfer of slurry bubble columns at extreme conditions

El Mahdi Lakhdissi

Slurry bubble columns reactors have many applications in chemical, biochemical and petrochemical industries. They are known by their advantages during operation and maintenance such as high heat and mass transfer and low operating costs which make them more efficient comparing to the other multiphase reactors.

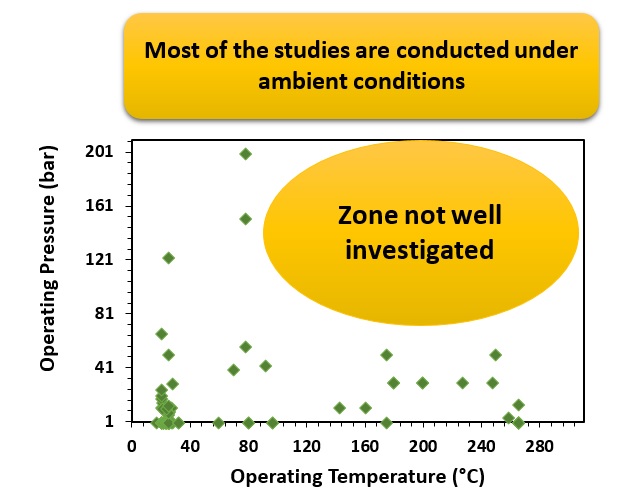

However, a better understanding of the hydrodynamics aspects and mass transfer coefficients that affect significantly the performance of those reactors are not well understood especially in the presence of solid particles. Also, almost all the previous work were carried out in ambient conditions regarding pressure and temperature or just treated high pressure or high temperature separately.

The presence of solid is also poorly understood because various authors tried to understand the impact of solids in terms of macroscopic quantities such as the apparent viscosity of the liquid phase. However, only few studies were concerned about the effect of particle size, solid concentration and catalyst degree of wettability on bubble coalescence and breakage within the column. In addition, there are many discrepancies in term of the mechanisms that explain the solid particles impact.

This work will be mainly concerned about the investigation of the hydrodynamics such as gas holdup, bubble rise velocity, bubble chord length and bubble size distribution and mass transfer aspects such as the volumetric liquid-side mass transfer coefficient of slurry bubble columns. The work will be conducted at high pressure (up to 30 bars), high temperature (up to 220C), low solid concentrations (up to 10%) and with different particle sizes (micron size). This will be done by using several measurement techniques such as pressure transducers, dissolved oxygen probe and fiber optic probe.

Compartment modeling of Bubble Column Reactor based on Computational Fluid Dynamics

Shuli Shu

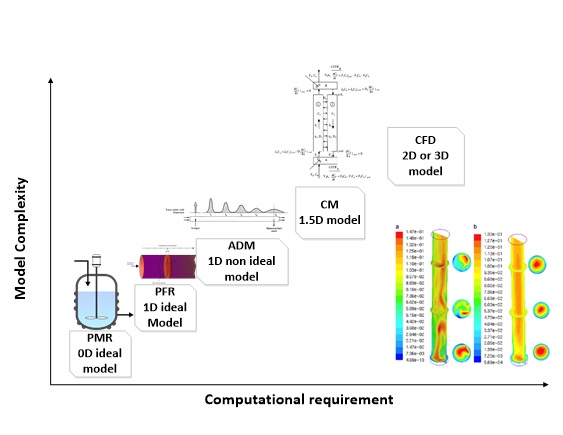

The scale-up of bubble column reactors (BCRs) is still changeling due to their complex hydrodynamics, mass transfer and chemical kinetics. Computational Fluid Dynamics (CFD) is becoming an alternative tool to predict the hydrodynamics of BCRs. However, CFD coupled with chemical reactions is still very difficult due to numerical instability. In this work, we try to develop a compartment model, which reproduce the hydrodynamics well and is stable when coupled with chemical kinetics, for the scale-up of BCRs. The developed compartment model can be coupled with chemical kinetics to predict the yields and selectivity of the slurry BCRs for hydroconversion of residue oil.

In compartment model, a BCR is divided into several compartments based on the hydrodynamics from CFD simulation. The average properties of each compartment and fluxes between the adjacent compartments are also extracted from CFD simulation. The developed compartment models should meet the mixing time predicted by CFD. This project is a part of Total chair under the supervision of Prof. Jamal Chaouki.

Development of a multiscale model for the simulation of mass transfer in gas/liquid bubble columns

Remi Demol

Bubble columns reactors (BCRs) are widely used in chemical, petrochemical, pharmaceutical and biochemical industries. These multiphase reactors are found in many processes using chemical or biochemical reactions between a gas phase, as bubbles, and a liquid phase located in the column. A third solid phase, suspended in the liquid phase, can be added to catalyze the reaction. Bubble columns have very good mass and heat transfer properties. Nevertheless, the scale up step is a difficult task. Maintain mixing conditions and similar hydrodynamic properties is not easy. Many studies have been made to estimate hydrodynamics parameters and get correlations.I am investigating the ways to create a multiscale model that describes as well as possible the mass transfer. Then, this work could give access to local values instead of average values on the whole column. For example, the volumetric mass transfer coefficient (kLa) which is, in fact, the product of two parameters: the liquid side mass transfer kL and the specific gas-liquid interfacial area a. I am working with OpenFOAM to run these simulations. This work could be useful to find news scale-up rules.

Microwaves-assisted demetallization and desulfurization of heavy petroleum oil using a developed demetalization agent

Mai Attia

One of the decisive issues that face the waste oil since long time ago is the inadmissible level of contamination by both metals and sulfur. In fact, such issue induces a jeopardy influence throughout the refinery processes because of severe damage to the contact surfaces. Furthermore, it gives rise to numerous environmental problems for both the humanity and the atmosphere.

This work presents a novel technique for metal and sulfur removal from heavy petroleum oil using a developed demetallization-desulfurization agent (DM-DSA). The developed method leads to break down the chemical bonds between the extracted materials and the network of the feedstock. Such a technology does not affect the yield of the end-product, compared to the conventional demetallization and desulfurization methods, as a result of its selective removal. Electromagnetic irradiation is employed to take advantage of the tremendous interaction between microwaves and metals. The selective heating of such a technology leads to create a local high temperature, compared to the temperature of the bulk oil, in where the reaction happens.

Objectives

- Valorization of the heavy crude oil by removing both metals and sulfur from its chemical network through a reaction with a developed DM-DSA in presence of electromagnetic irradiation.

Methodology

- to develop a DM-DSA that fulfills the required chemical and electric properties.

- introduce of microwave heating as the main heating mechanism in the removal process.

- investigate the influences of the main process parameters, such as DM-DSA dosage, reaction temperature, irradiation power, microwave frequency (if possible), residence time.

- compare the impacts of the exposure to electromagnetic irradiation against that of the superficial heating mechanism on the process efficiency.

- develop a downstream method to recycle the DM-DSA as well as the recover extracted metals.

Heterogeneously catalyzed conversion of biomass to bio diesel applying an integrated system of microwave and ultrasound

Siavash Fadaeerayeni

Finding an alternative fuel has attracted considerable attraction in recent years due to limitation of traditional fossil resources and increasing of crude oil prices as well as concern over greenhouse gas emissions. Transesterification using homogeneous base catalysts is one of the most commercially useable methods to produce biodiesel. However, cheaper feedstocks like waste oils, animal fats cannot be converted to biodiesel using the conventional base mediated process, as the FFA of oils creates the problems of saponification and also the process of recovery of catalyst is costly. In this regard, heterogeneous acidic catalysts could be a promising alternative since these catalysts are capable of handling esterification and transesterification of triglyceride simultaneously and also regenerable. Regardless of all these benefits, heterogenous acidic catalyst are suffering from some drawbacks such as the slow rates of reaction necessitating higher operating temperatures and formation of three phases together with oil and alcohol, which leads to diffusion limitations thus decreasing the rate of the reaction. To alleviate this issue, the current project aim at enhancing the conversion yield of direct transesterification over a heterogeneous acidic catalyst applying microwave and ultrasound that can enhance the mass transfer rate between immiscible phases, simultaneously diminishing the reaction time. Moreover, considering microwave absorbing property of catalyst and rapid heating of microwave which leads to localized high temperature on the catalyst surface, could provide this process with operating lower temperature and pressure. Which will contribute positively to the costs associated with reactor design, energy, and operational costs of reactor.